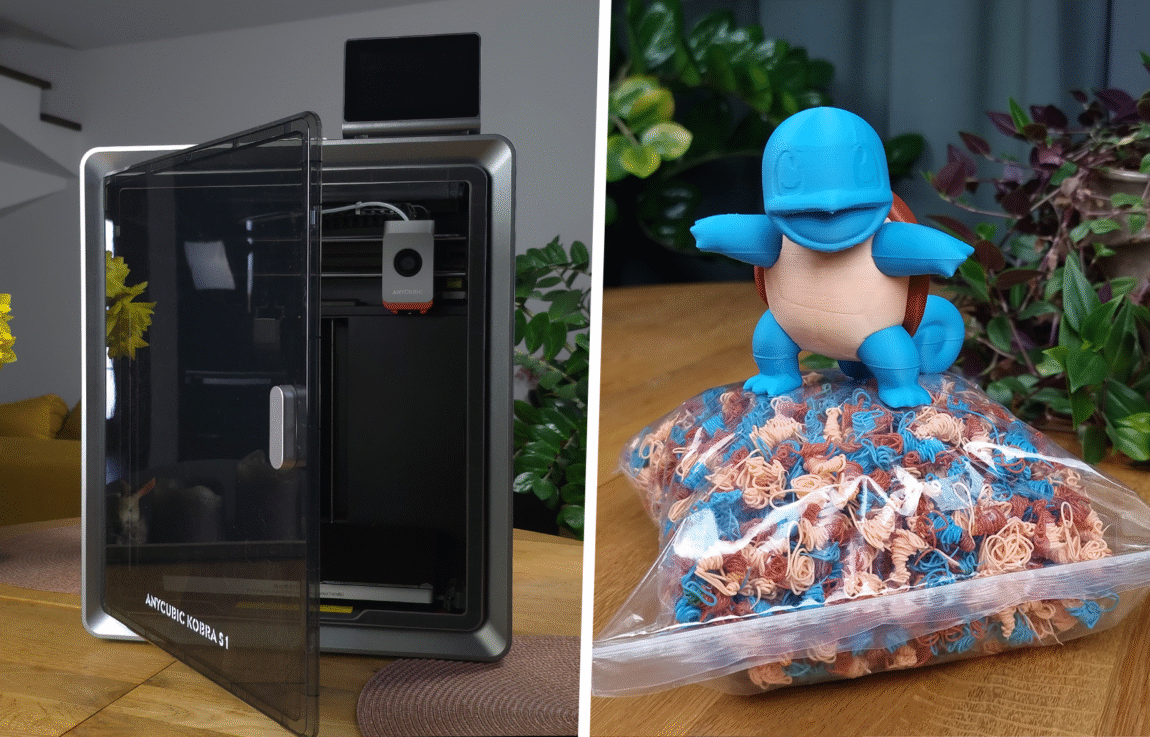

Are you dreaming of a 3D printer that is beginner-friendly but also offers features worthy of professional attention? The Anycubic Kobra 1 ACE Combo is the new member of the Anycubic family, which at first glance seems like the ideal balance between price, performance and convenience. But does this model really live up to its promises? Is it able to print accurately, quickly and effortlessly, as the manufacturer claims?

In this review, we'll dive into the world of the Kobra 1 Ace Combo - from first impressions out of the box to real-world testing with various types of models. I'll share what the strengths and weaknesses of this model are, how it compares to the previously tested Flasforge M5 Pro, and who it would be best suited for. Without further ado, let's get started!

Anycubic Cobra 1S + Ace Pro

Assessment:

What did we like?

What didn't we like?

Unboxing

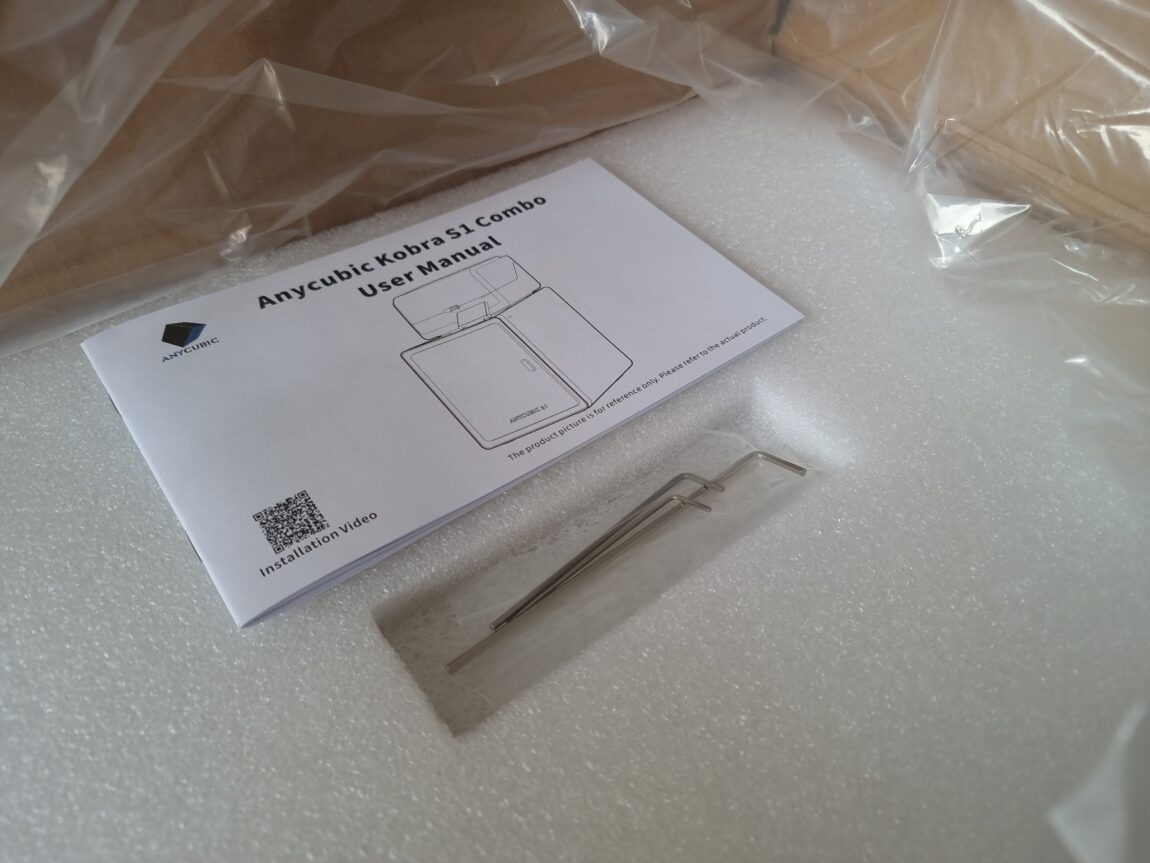

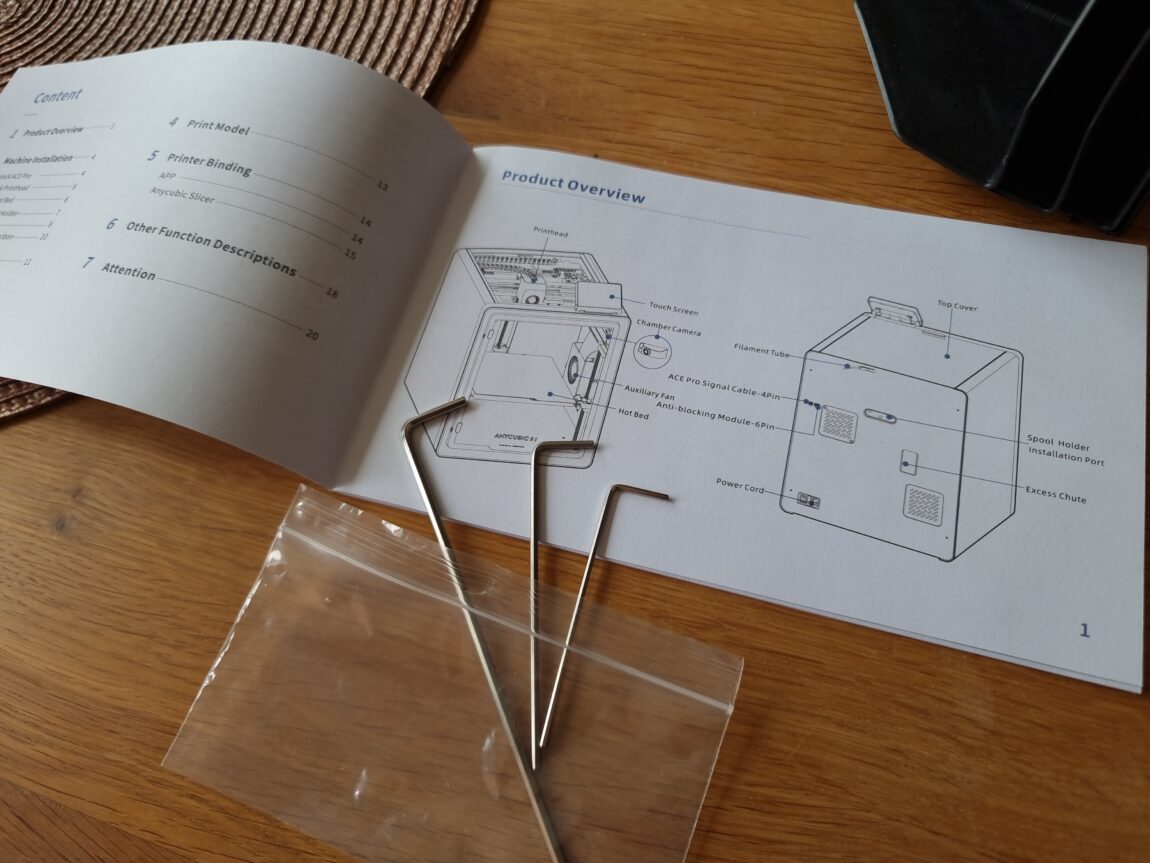

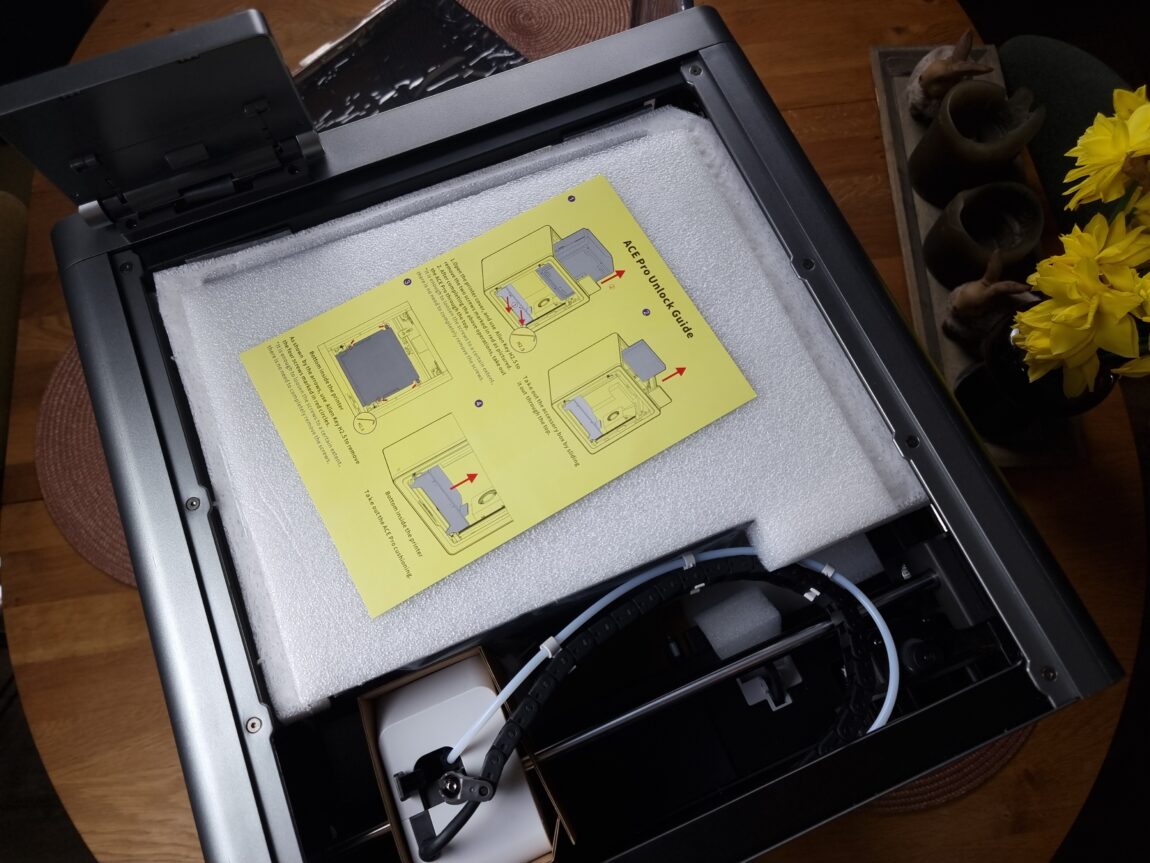

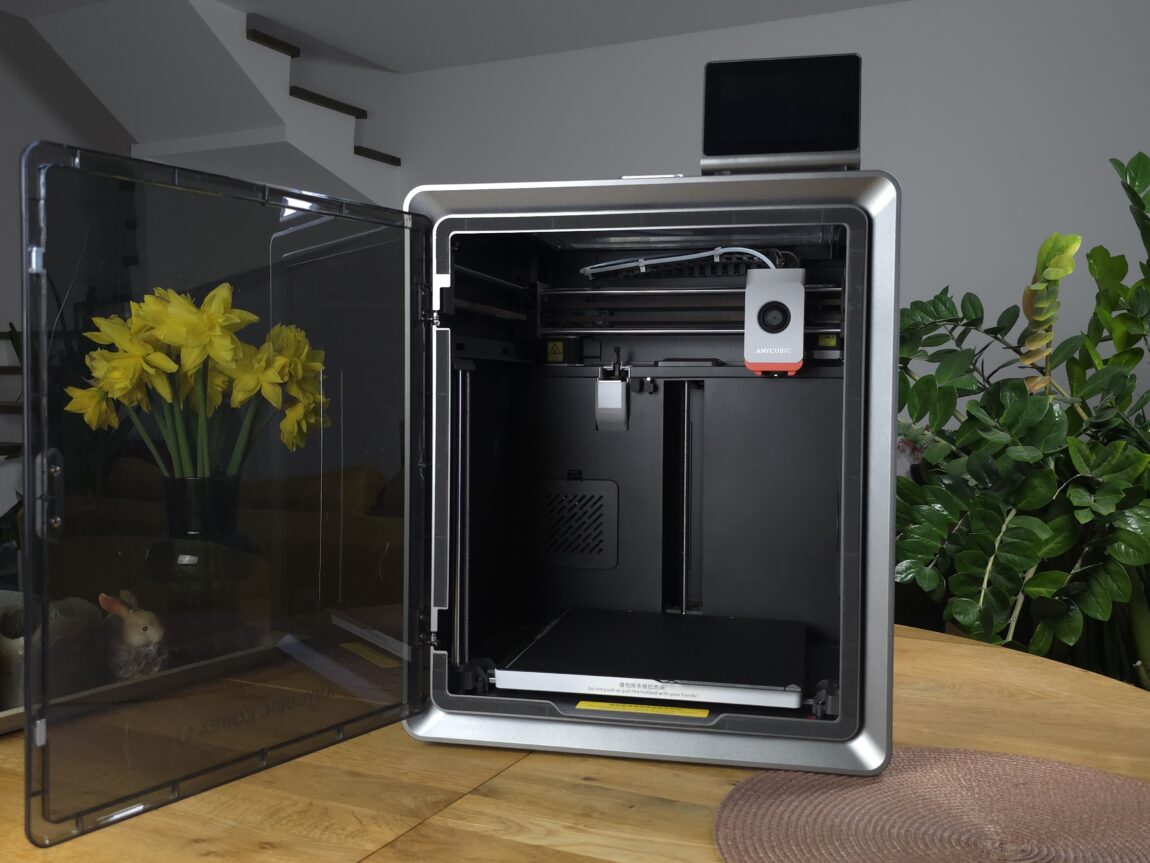

The Anycubic Kobra S1 Combo arrived in a standard box with cutouts on the sides for easier carrying. The box is a bit heavy, but it's definitely possible for one person to carry it. Inside, the 3D printer is securely packed with foam padding.

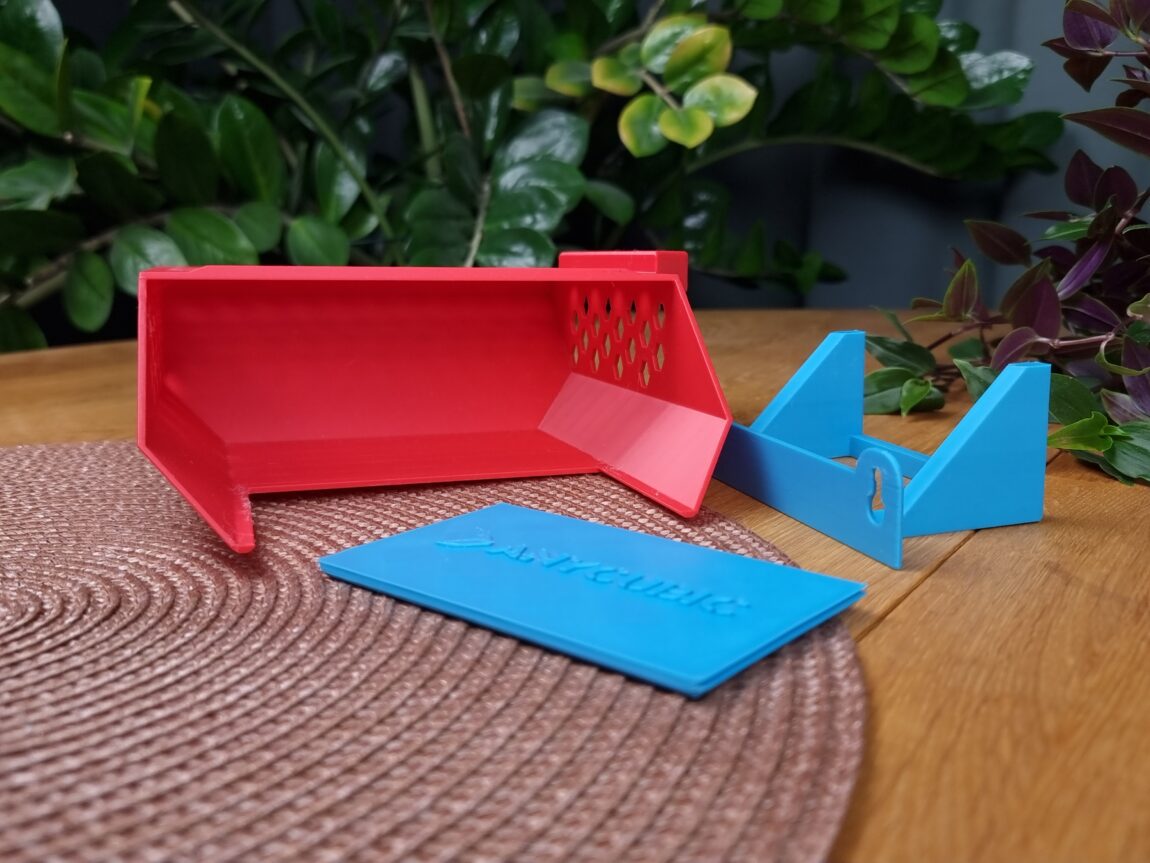

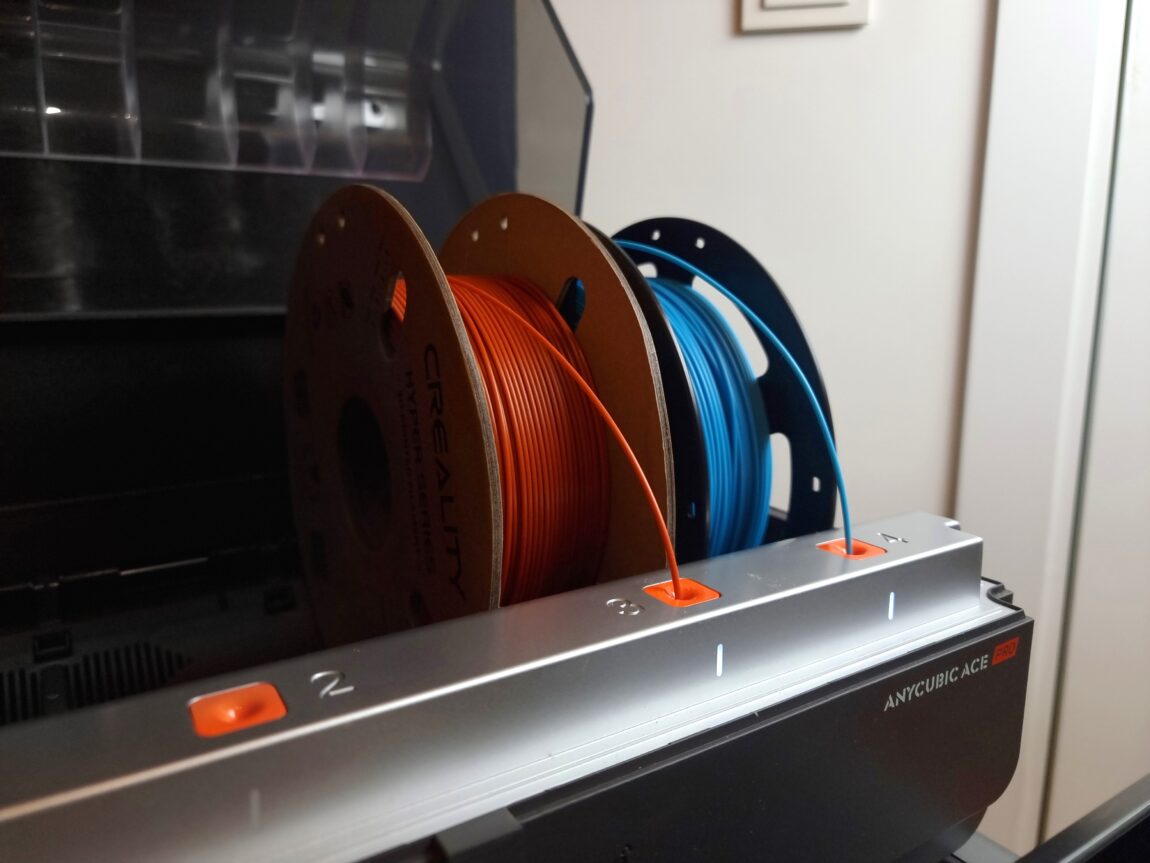

Two sets of PLA plastic rolls arrived in smaller boxes, each with four different plastic colors. In total - 8 rolls of different colors. The boxes were a little battered, but the plastic rolls themselves and their vacuum packaging were neat and undamaged.

Although it is possible to unpack a 3D printer alone, it was much faster and easier to do it with help. The printer itself came with a lot of protective padding, the ACE Pro system, and a simple cardboard box with all the necessary tools, parts, and accessories.

First launch

Once you have assembled the Kobra S1 Combo, the instructions very simply and clearly outline all the initial startup steps, explaining how to pair the printer with their Anycubic mobile app. Before first use, the 3D printer runs several different calibrations and tests that ensure proper further operation of the device.

The instruction booklet also easily explains how to load and feed plastic rolls into the ACE Pro system and, if non-manufacturer plastic is used, how to assign the color and plastic type to the system for those rolls.

Usage

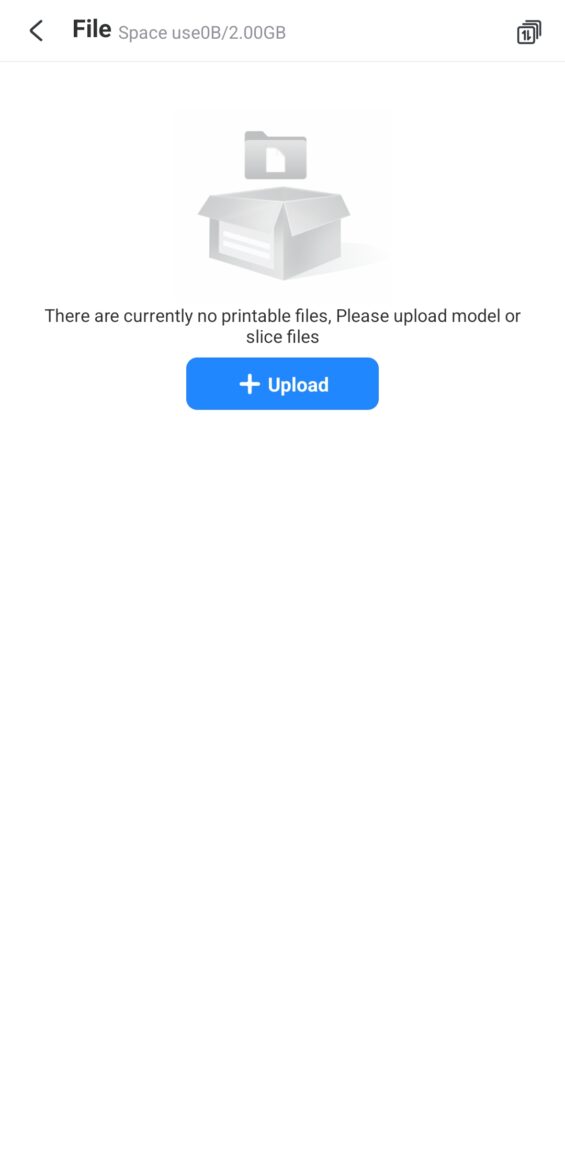

The printer screen comes pre-installed, so there's no need to screw or attach anything. It's touch-sensitive and responsive, and the user interface is simple and clear. There were only two instances where the system didn't work as I expected.

In one case, it was due to lack of space on the printer itself or on the USB flash drive, in the other - when starting the printer for the first time and trying to assign plastic colors in the ACE Pro system. In the first case, it was enough to free up space by deleting unnecessary model files, and in the second - simply rebooting the 3D printer.

Speaking of rebooting - both the printer and the Ace Pro have a physical on/off button only on the back. I would say it's a bit inconvenient, especially when the device is leaning against the wall. To make it more convenient - I used an extension cord.

Auxiliary functions

This 3D printer has several features designed to save prints in certain situations. If the power goes out during a print, the printer remembers the instructions given and usually allows you to continue the print. However, this is not automated, so the print continuation must be enabled manually.

When connected to the ACE Pro system, the Filament Backup feature can be enabled in the filament selection settings. In this case, if you load a couple or more rolls of the same filament, when one runs out, the next one will automatically be selected and the print will continue.

In my case - I didn't have identical plastic rolls during testing, so I "tricked" the printer and tested with two rolls of different colors. The transition from one plastic to another is almost imperceptible (apart from the color difference). This feature can be extremely useful when printing more complex and large-volume projects unattended.

The printer has several different auto-calibration settings that the printer will remember to remind you of each time before starting work. A full calibration takes about 20 minutes and is available in the settings section.

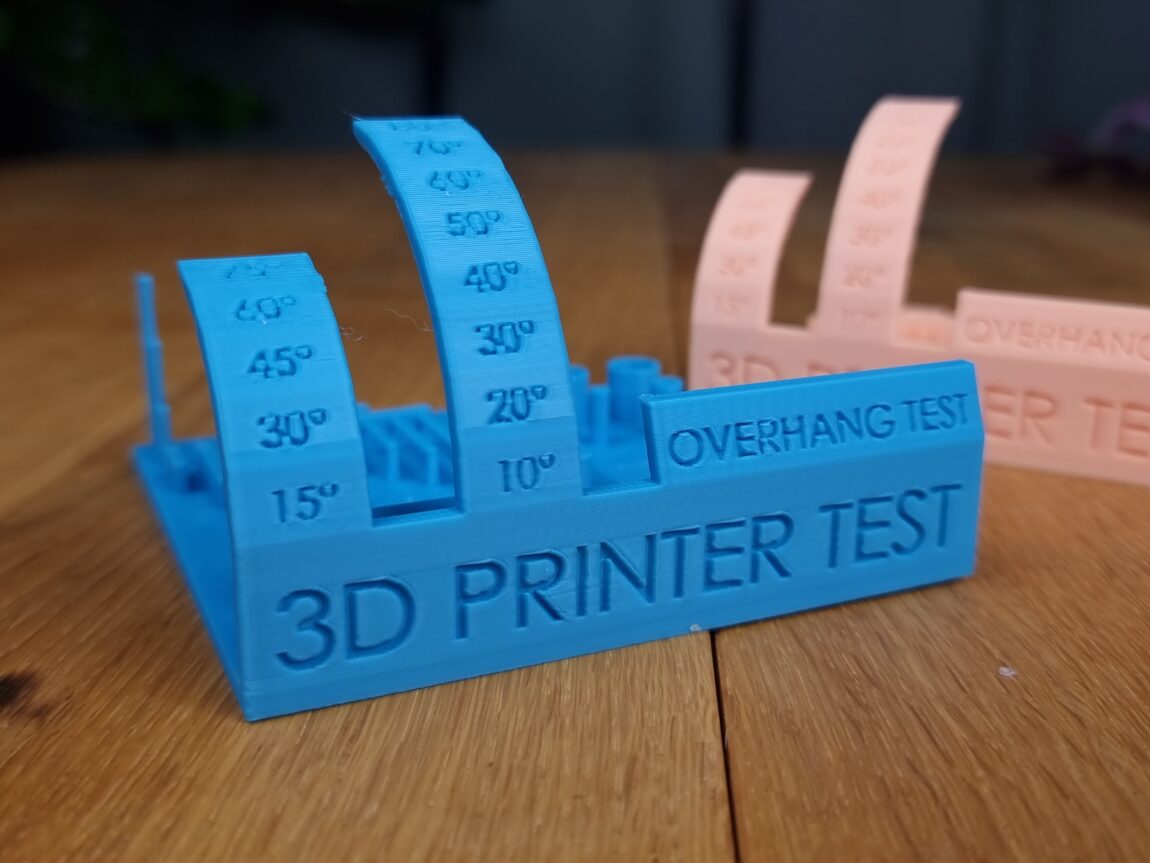

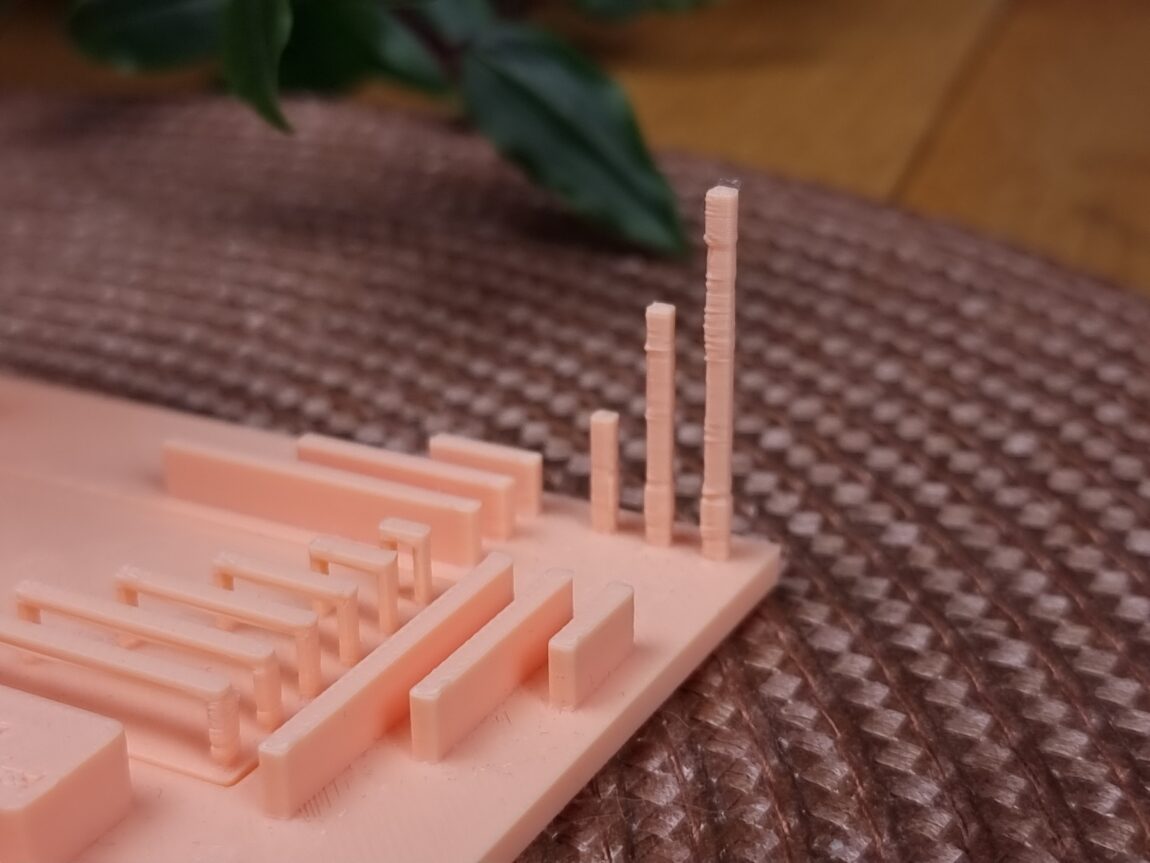

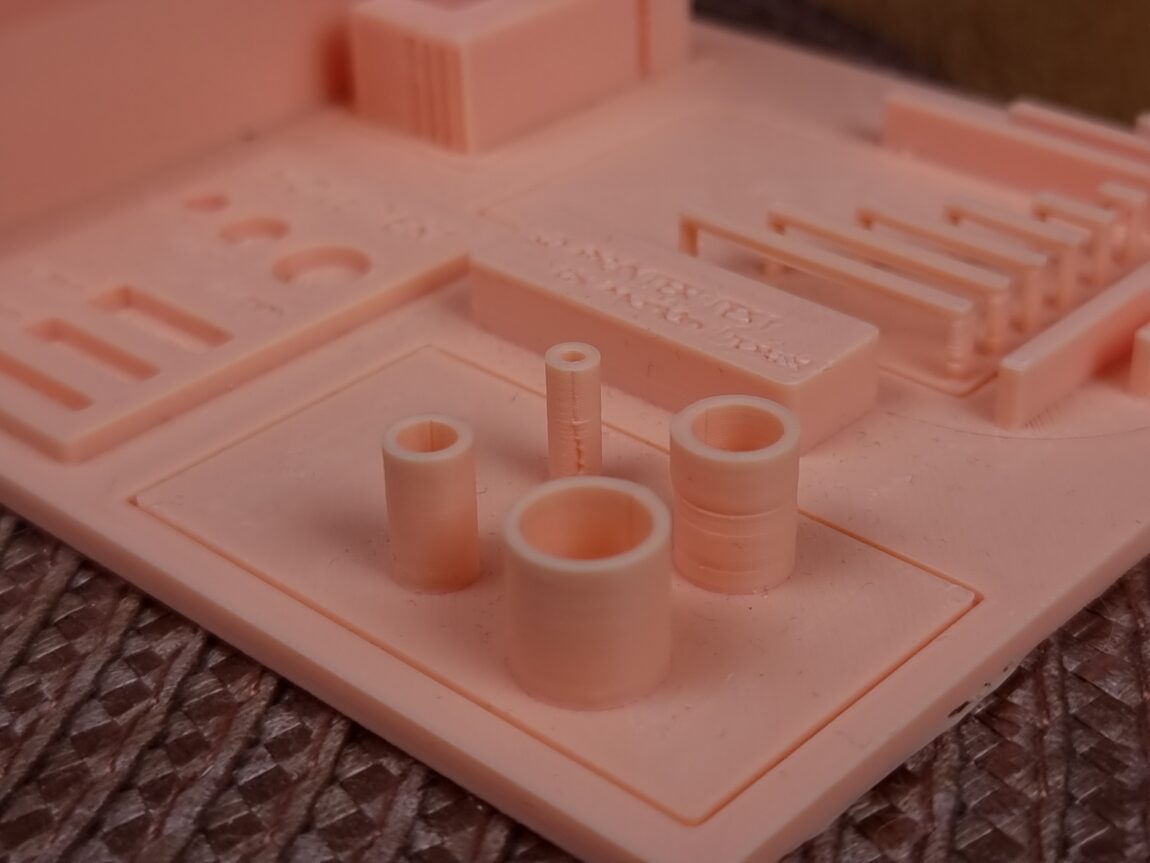

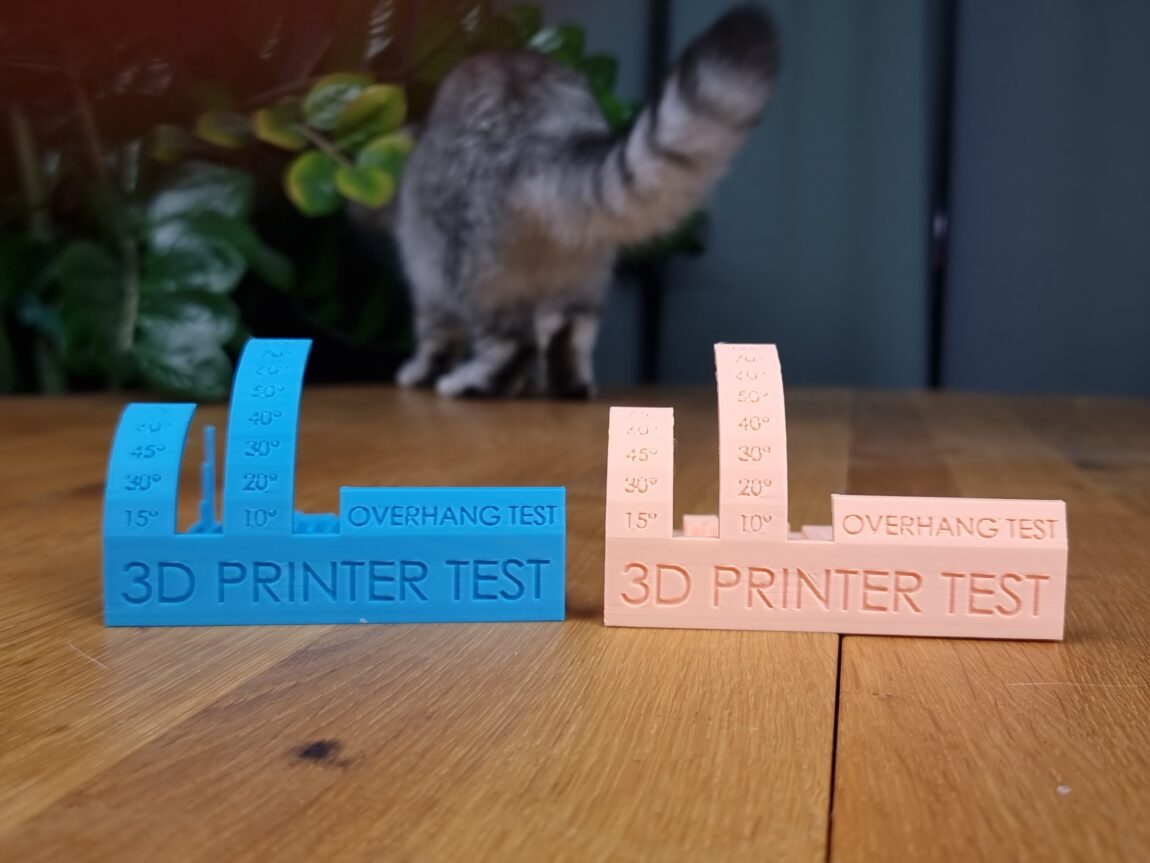

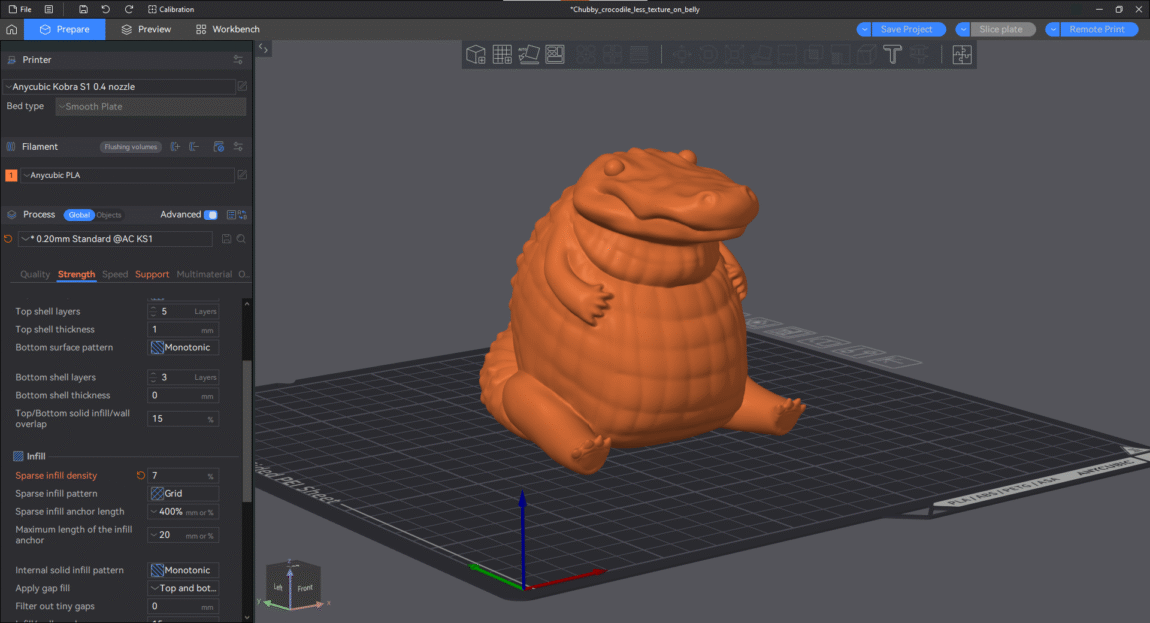

Print quality

The print quality depends on the print settings selected in the slicer program and on the 3D model itself. With completely factory settings and ensuring that the first print layer adheres well to the platform, the models are of high quality. In most cases, no obvious defects are visible.

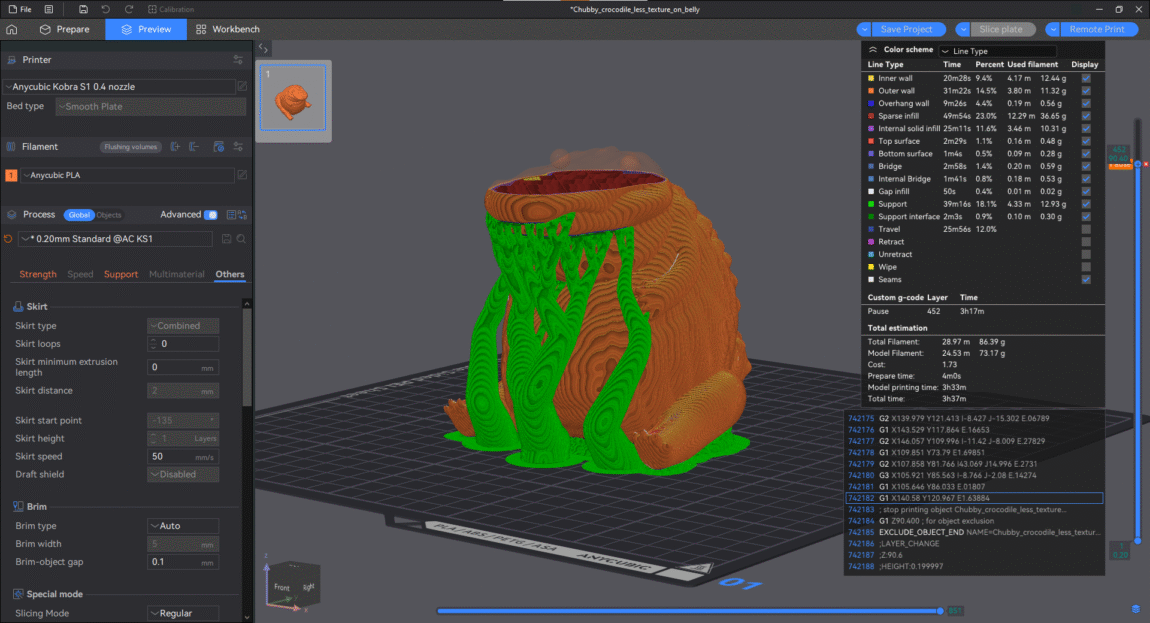

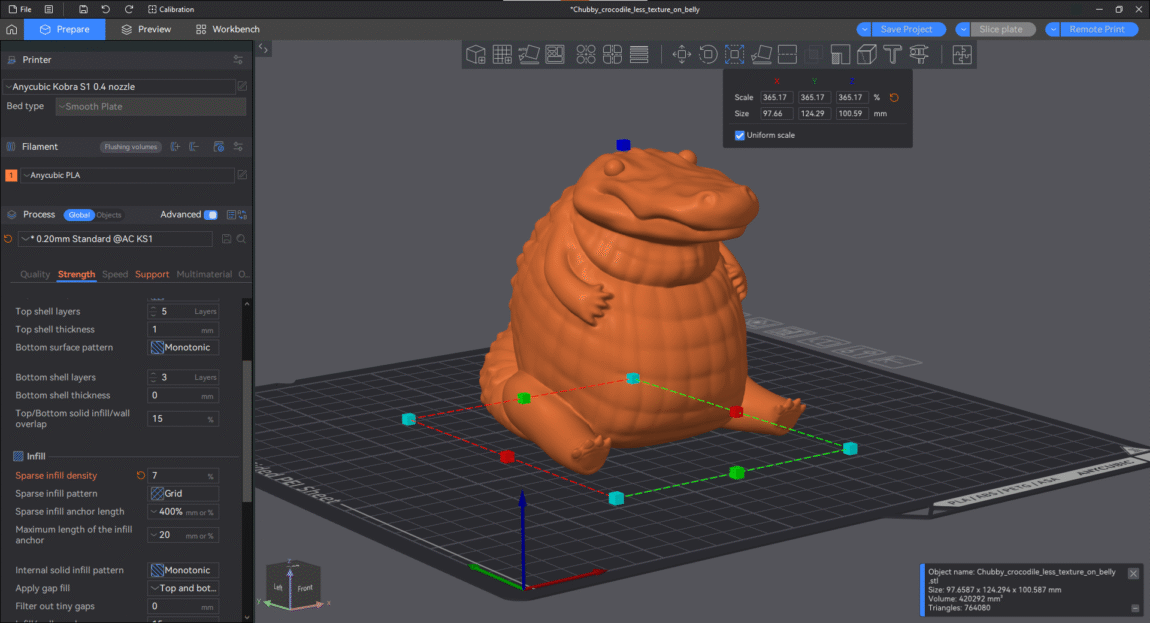

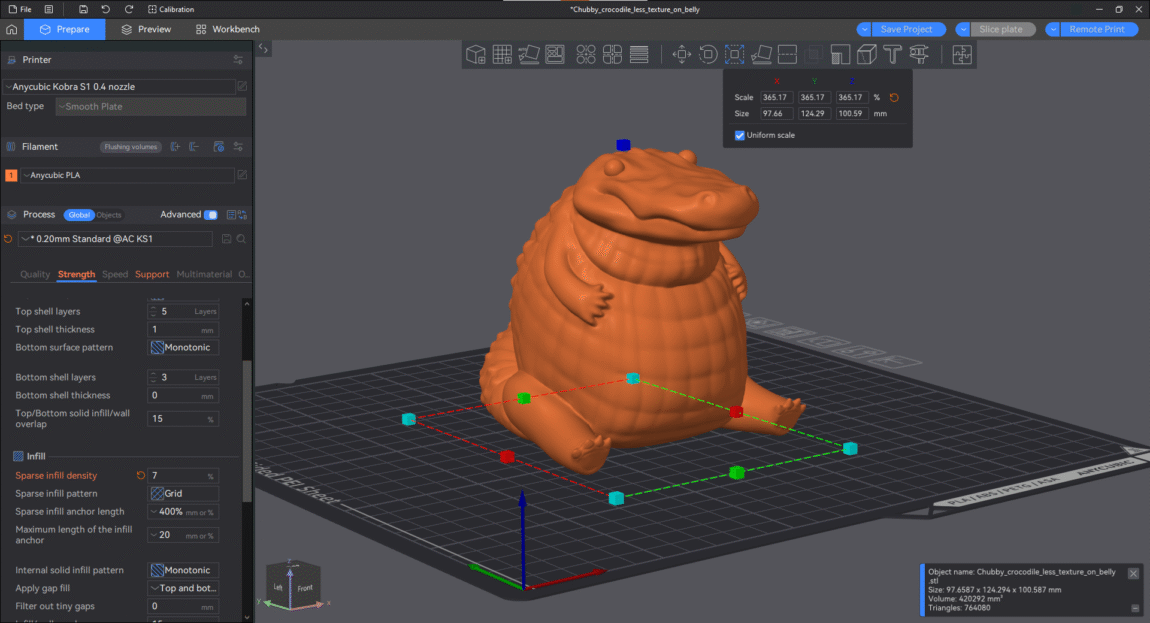

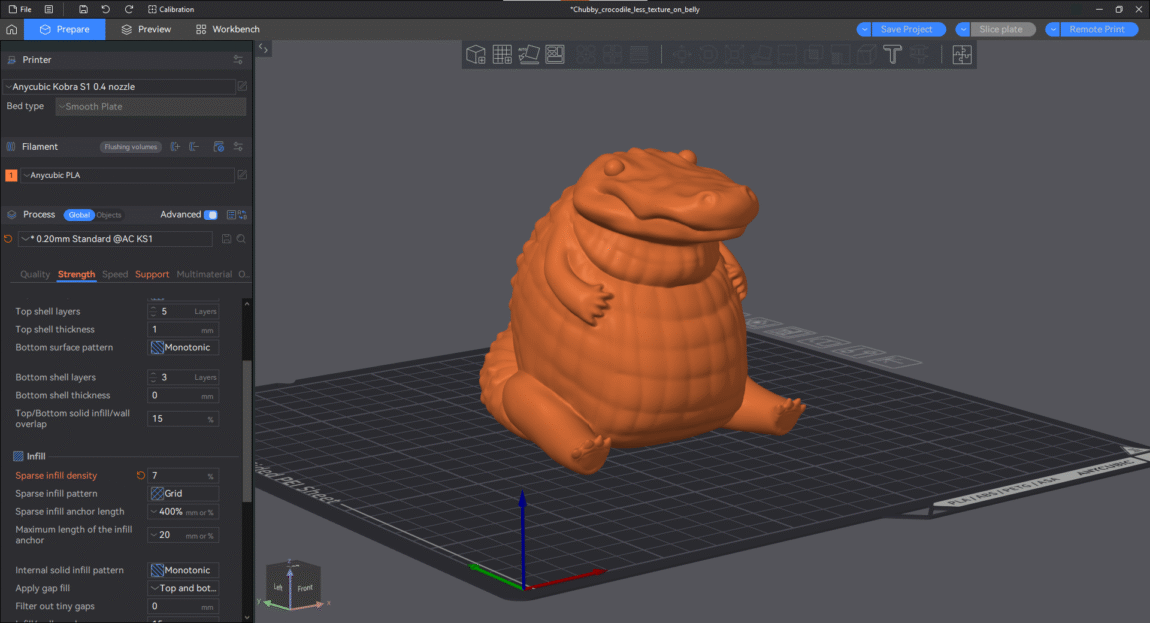

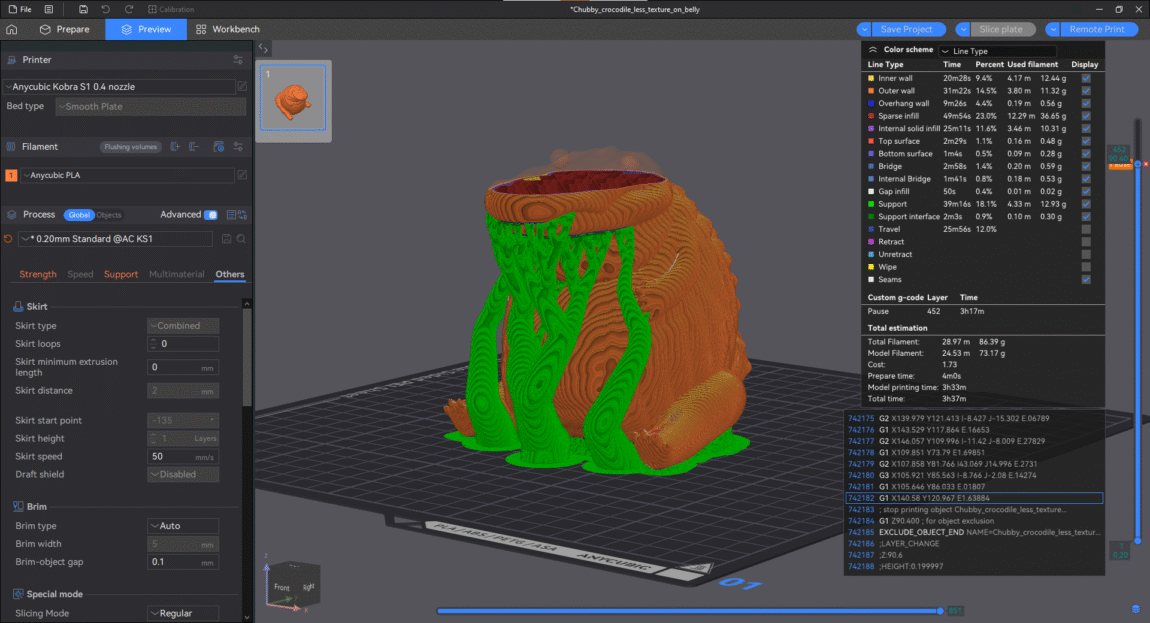

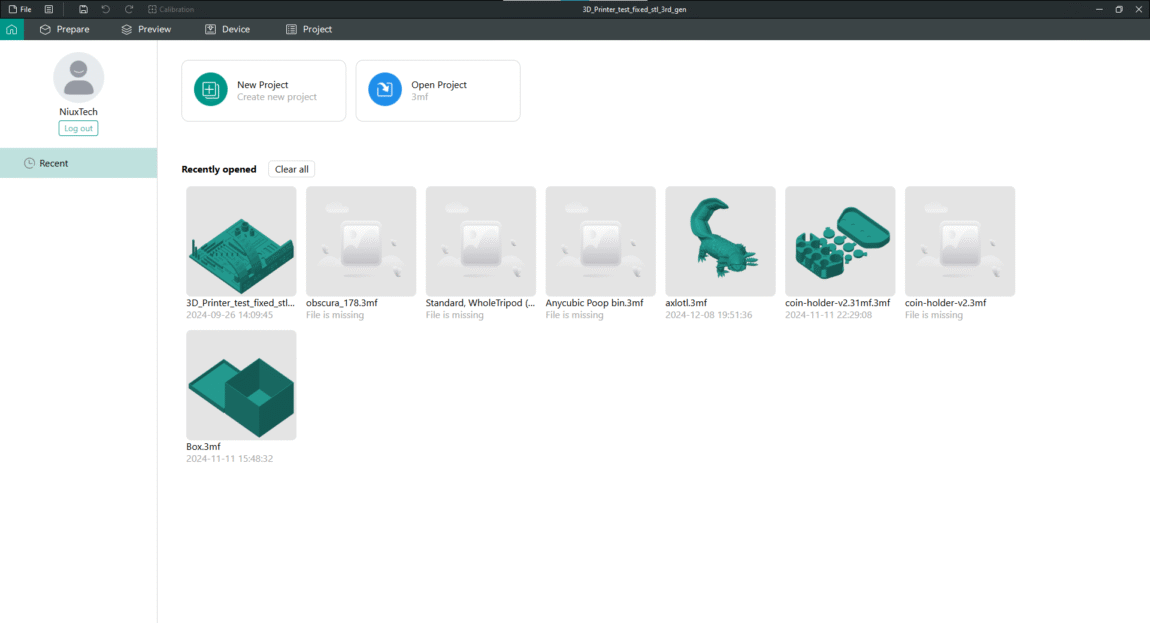

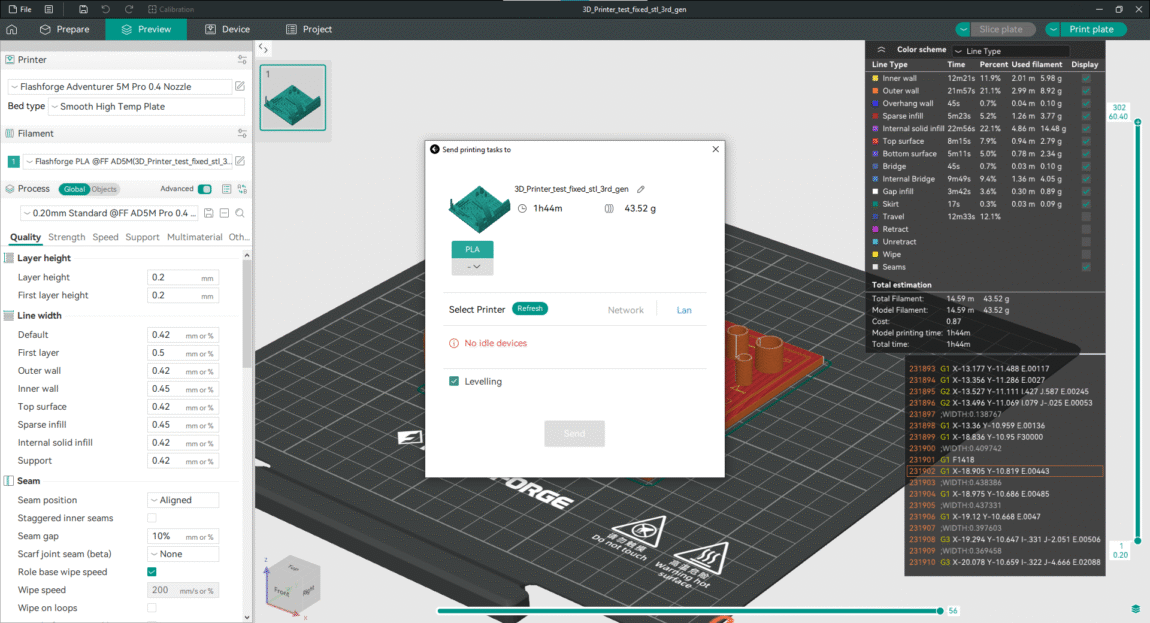

The Slicer program comes with a USB key, but I personally downloaded their latest version of the Anycubic Slicer Next slicer, for processing and converting 3D models (.obj, .stl files) into g-code commands that the printer understands.

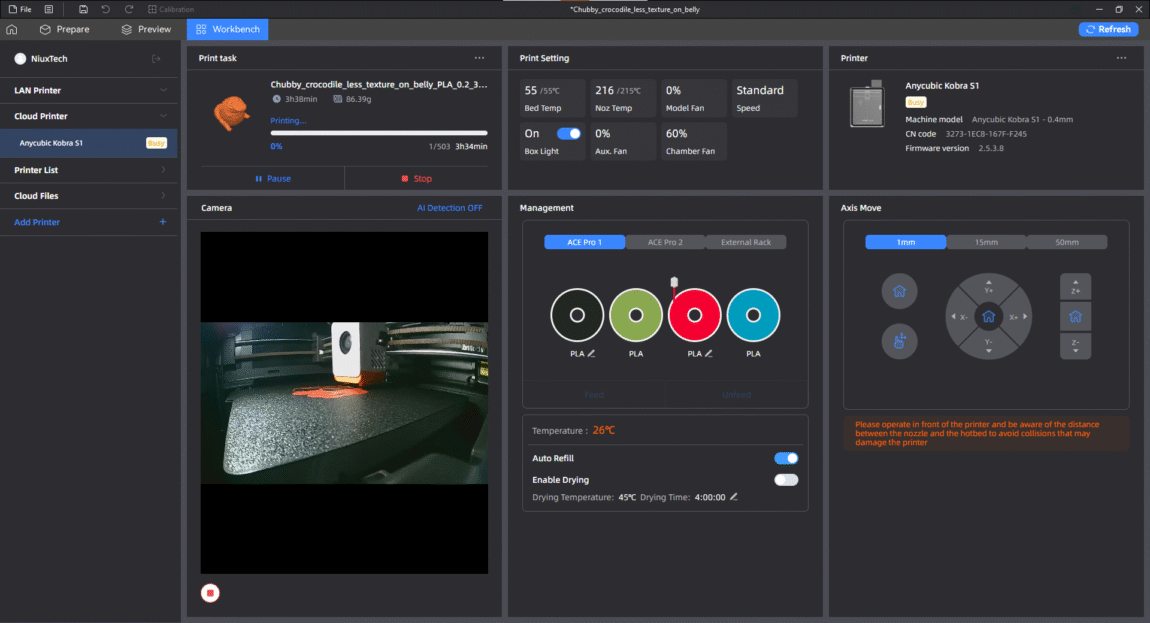

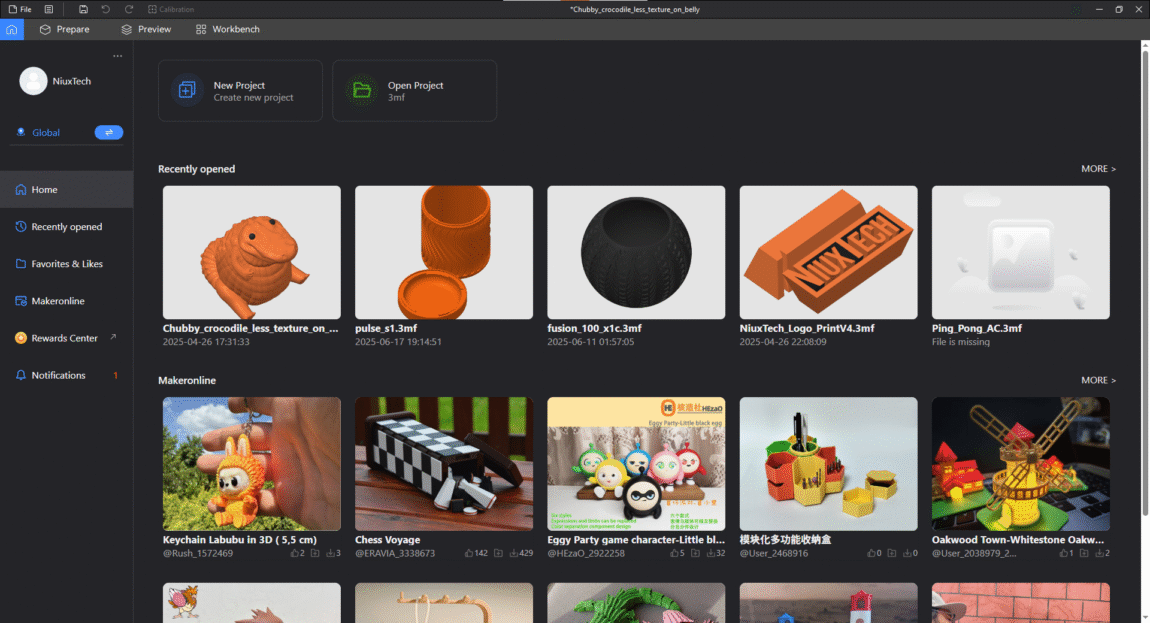

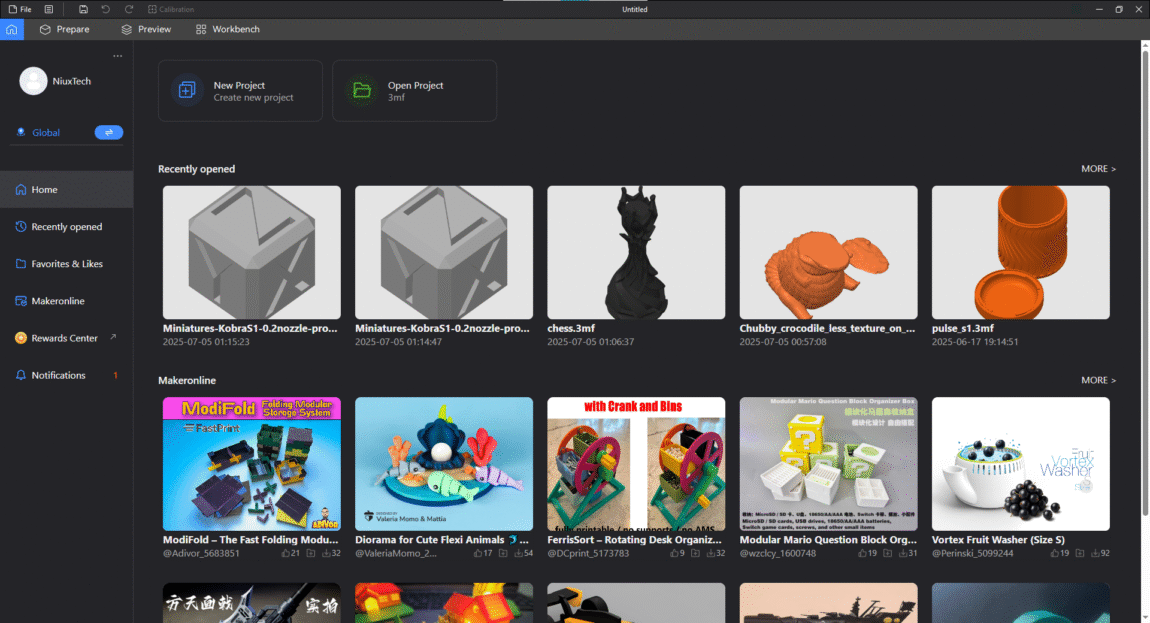

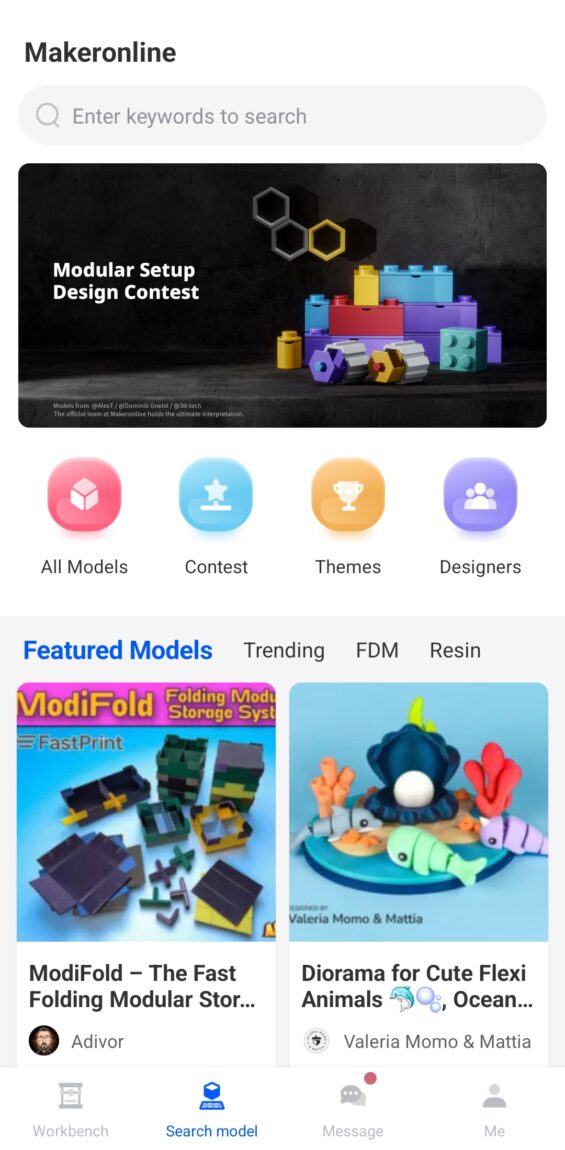

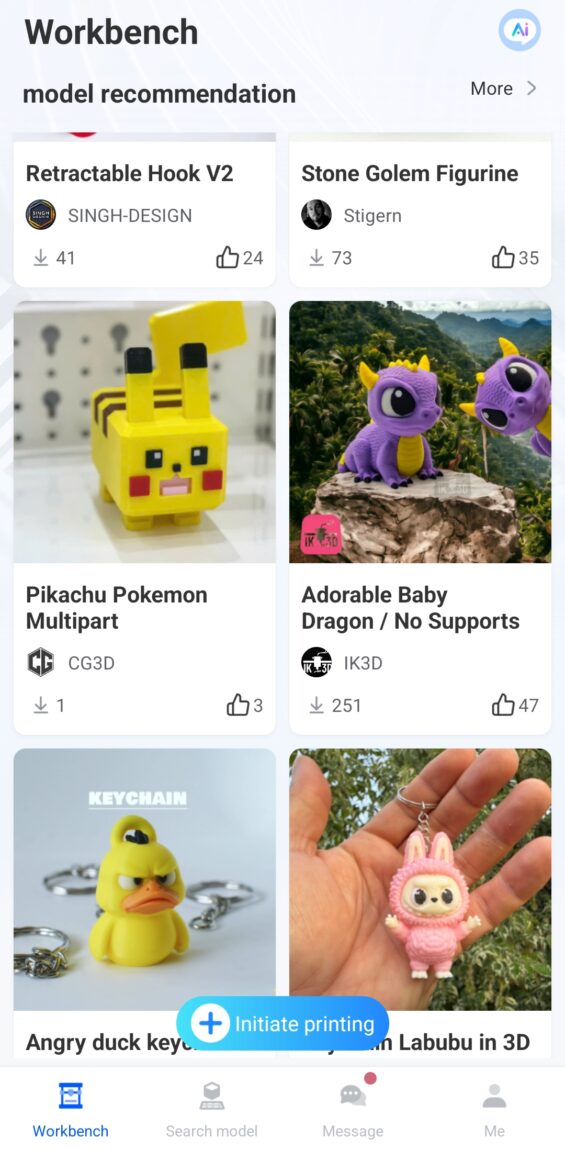

This is another fork of the existing Orca Slicer app, with custom/calibrated print profiles and several remote printer monitoring and control features. However, it also has their own Makeronline 3D model sharing platform integrated, which is what I mainly used during the testing period.

The ACE Pro has a built-in drying function to keep plastic rolls in optimal conditions. When plastic is stored in an open environment for long periods of time, it can absorb moisture, which can negatively affect print quality or even disrupt the printing process altogether.

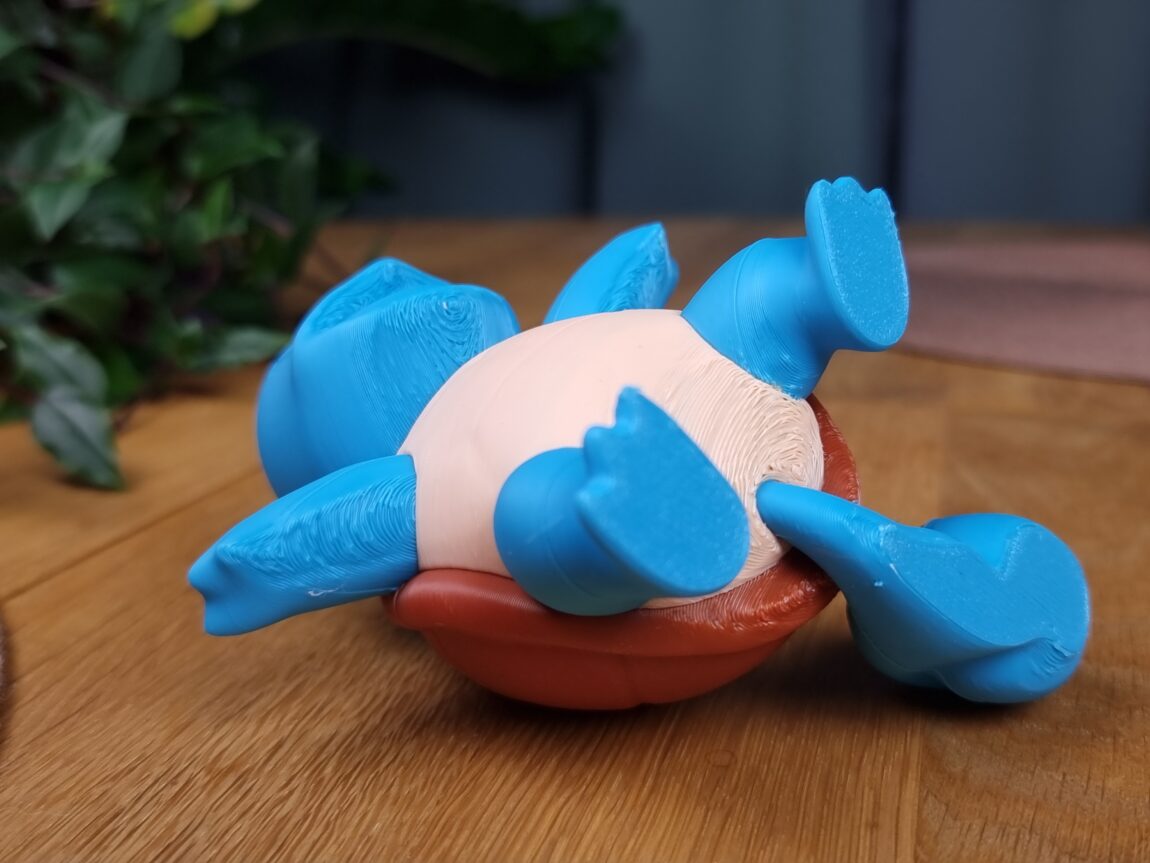

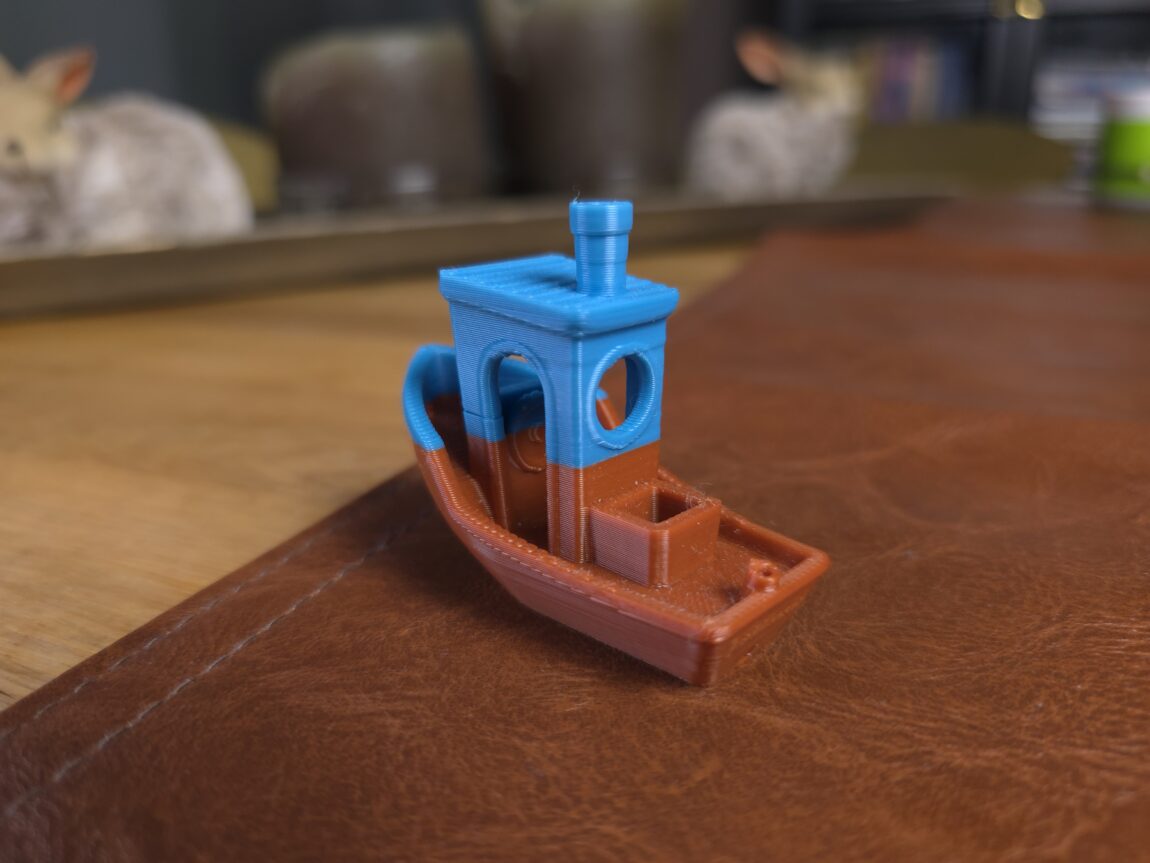

Multi-color printing

One of the main features of this printer is that with the help of one or two ACE Pro systems, it can print up to 4 or 8 different colors respectively. By choosing a multi-color project, you will have the opportunity to select your desired / available plastic colors before printing.

These 3D models are produced in the most perfect way, but it is important to mention a few nuances that are directly related to the color change of this system. Every time the printer changes color, it throws out some plastic. This ensures that the transition is neat, without blending with the previously used color.

It took a little over two hours to print a simple one-color model. Meanwhile, when printing it in 3 different colors, the printing time stretched to 24 hours and left as much as 368 grams of waste. For comparison, the model itself weighs only 70 grams. So, when printing in several colors, a lot of time is sacrificed and much more plastic is used.

Comparison with Flashforge Adventurer 5M Pro

PRINT QUALITY

Both printers print at very similar speeds. The Anycubic Kobra S1 may be a little faster, but overall speed and quality depend mostly on settings and optimization. The print quality turned out to be very similar as well.

True, the Flashforge Adventurer 5M Pro comes with two extruder heads: 0.6 mm and 0.4 mm. Additionally, a 0.2 mm head can be purchased from the manufacturer itself, which allows for higher quality prints.

At the time of this review, Anycubic does not sell any other sizes of heads, except for the standard 0.4 mm. However, the manufacturer itself indicates that it is possible to use 0.2 / 0.6 / 0.8 mm options, which would most likely have to be sought out and purchased from third parties.

DESIGN

In terms of design, both printers have some similarities - both look modern, both feed plastic from the rear, and the plastic roll holder is mounted in the same place (if the Kobra S1 is used without the ACE Pro). The Kobra S1 is slightly larger by a few centimeters in all axes.

With the ACE Pro system, it takes up significantly more space. The Adventurer M5 Pro's screen is integrated into the case itself, but occasionally doesn't respond to light touches. Meanwhile, the Kobra S1's screen is mounted on the top of the case, adjustable at a 90-degree angle, and responds perfectly to all touches.

However, it is worth noting that the USB port on this model is not integrated on the front, but on the right side. This is important if you plan to store time-lapse recordings or transfer model files using USB storage.

FUNCTIONALITY

The Anycubic Kobra S1 has different speed settings and is designed to print in up to 8 different colors. The ACE Pro provides a very quick and easy process for changing plastic rolls. There is no need to cut anything, just pull out and feed a new roll, and the printer takes care of everything else.

Another advantage of the Ace Pro system is that it keeps the plastic dry and ready to print. AI (artificial intelligence) can detect if something unusual happens during the printing process, which can help save time and plastic.

Flashforge, meanwhile, is much simpler and requires more human involvement. This model has the same capabilities for shooting timelapse videos, and its printing volume is a few centimeters smaller (220x220x220 versus 250x250x250).

HEAD REPLACEMENT / FAULTS

The 5M Pro printer supports different heating heads, and the replacement process is very simple and fast. Compared to the Anycubic S1 printer, it will require a little more effort. On the other hand, it is understandable, since the Kobra S1 Combo is a more complex system with more tubes and internal components.

The Adventurer 5M Pro is a much more basic model, so the probability of failures is also lower. When they do occur, it is clearer and easier to figure out where they occurred. On the websites of both manufacturers, you can easily find instructions that will help you diagnose and solve any problems that arise.

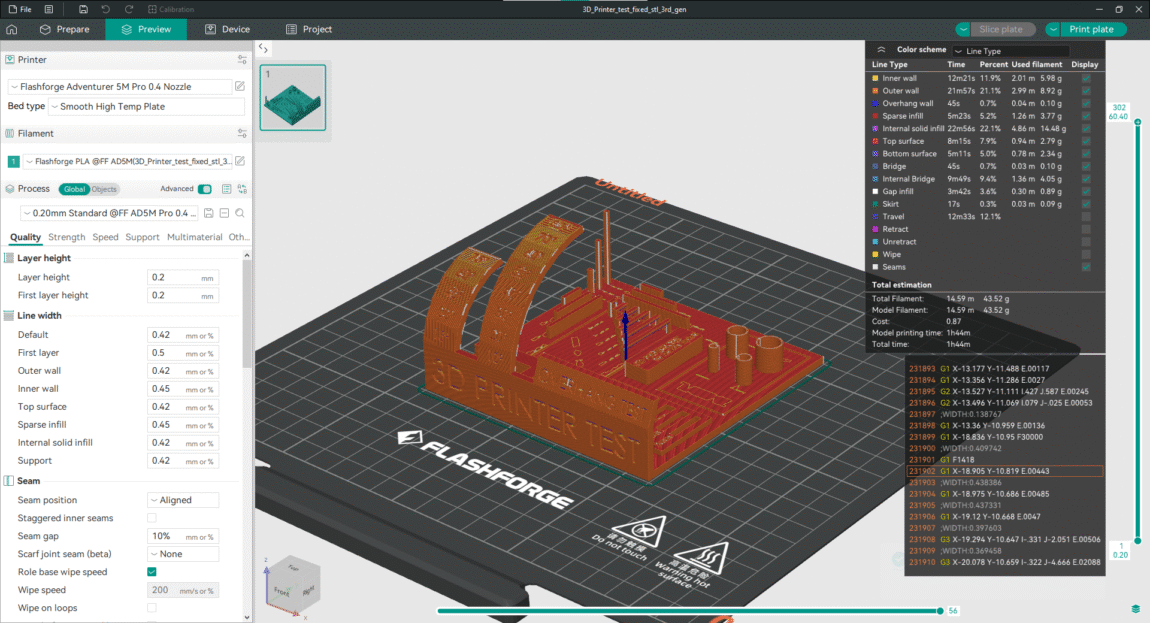

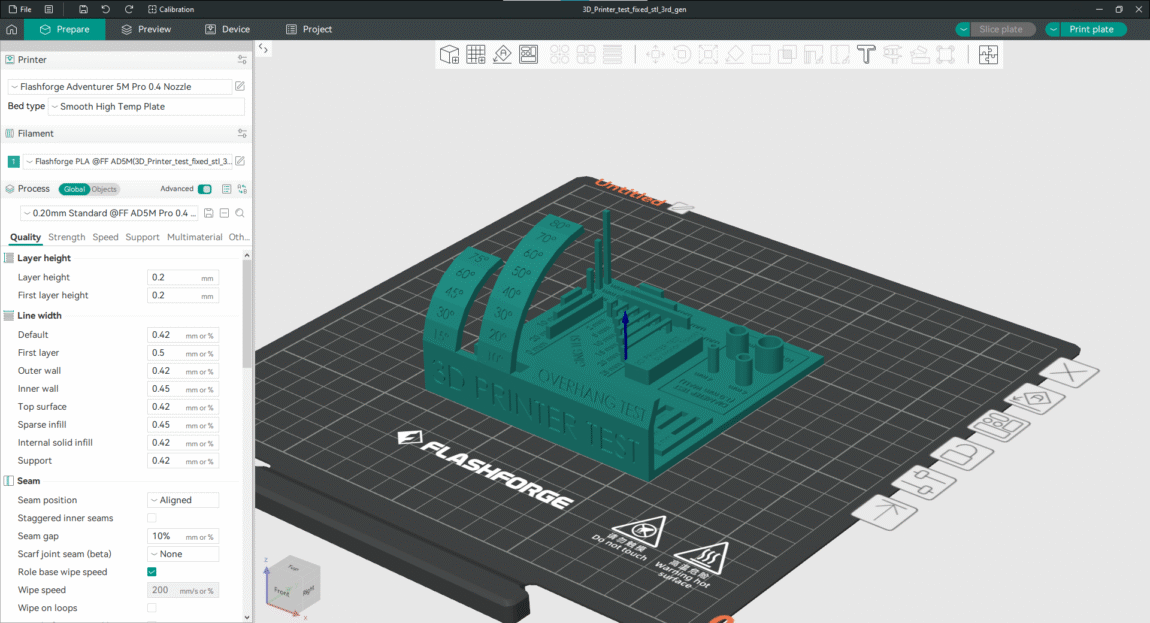

SOFTWARE

Both Orca Flashforge and Anycubic Slicer Next are forks of the Orca Slicer program, so they are very similar. The usage of both is almost identical - the settings are tailored to their own printers and plastics, but the programs can also be used with equipment from other manufacturers.

Both apps allow you to monitor and control your printers, as well as start printing remotely – just log in to your account and pair it with your printer. The main difference between them is that Anycubic has integrated the model sharing platform Makeronline.

Since this platform is relatively new, the selection of models is still limited, especially compared to other, more established platforms. However, one big advantage is that some models are already ready to print with the Kobra S1, so you can quickly download the model directly to the slicer and start printing immediately.

I also want to add that the Anycubic app has always worked smoothly in my time with it. Meanwhile, the Flashforge slicer app has logged me out of my account several times, so I couldn't use the remote launch and control features.

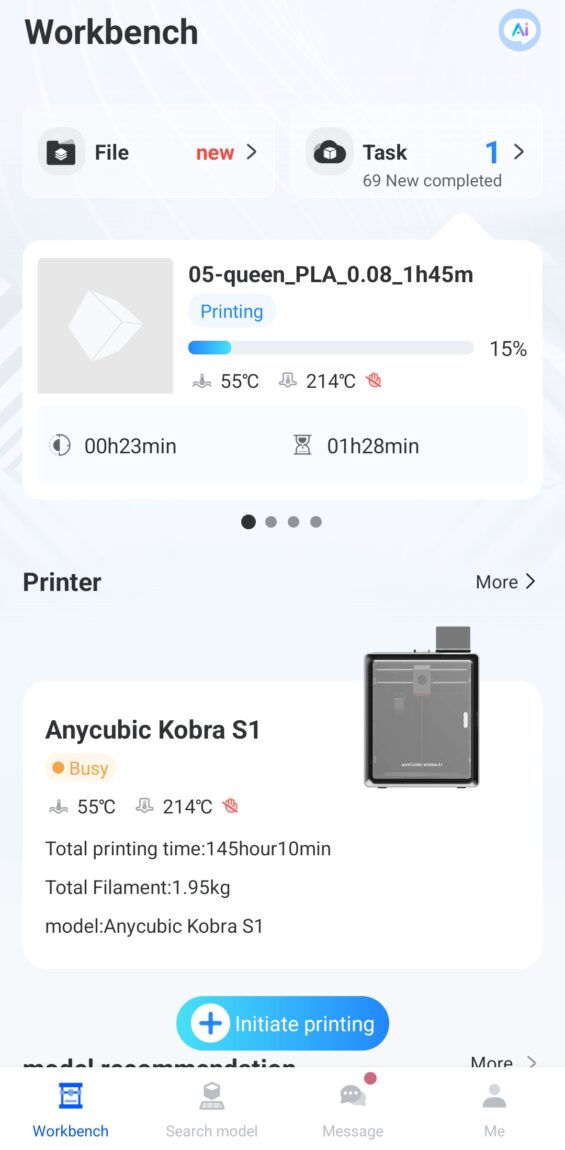

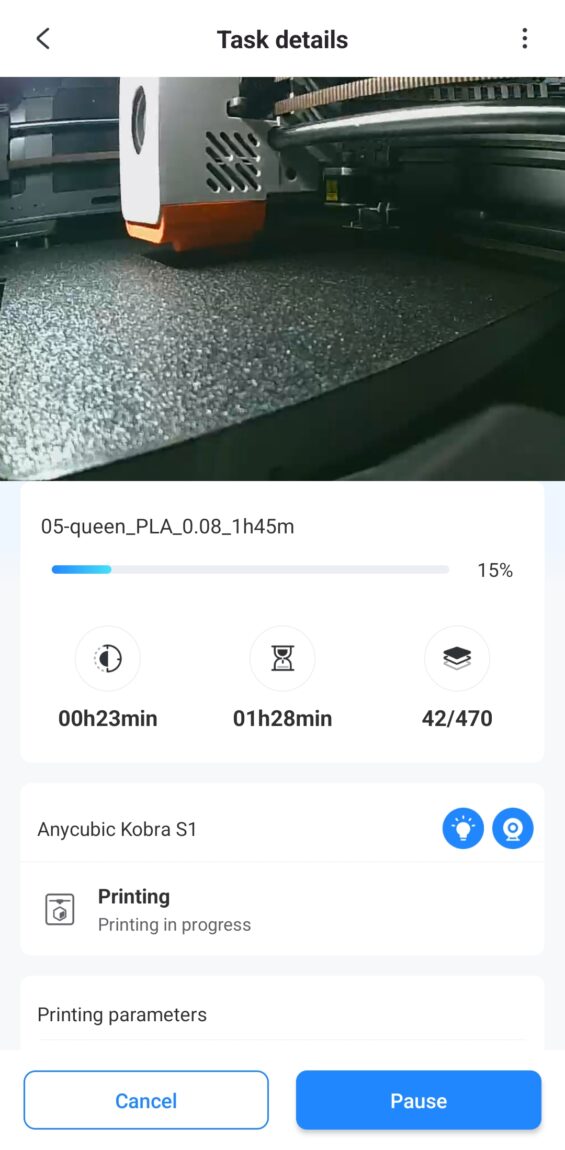

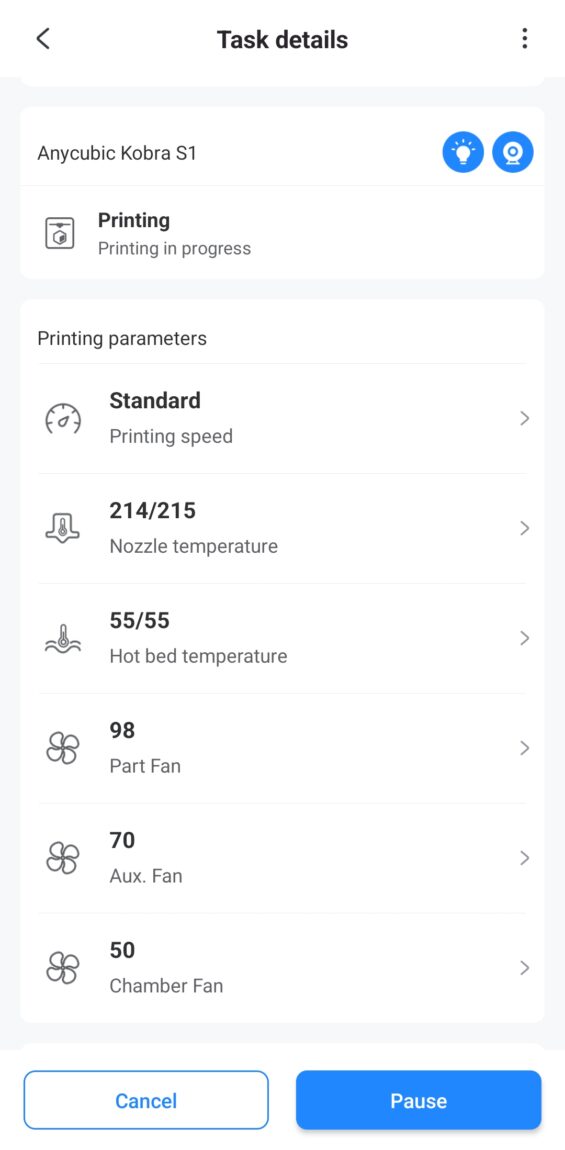

MOBILE APPLICATION

APPs are also similar to slicer programs. By logging in with your account and linking the printer, you can control and maintain the printer remotely. The Anycubic app even lets you start printing from the app and allows you to use their Makeronline 3D model browser.

Personally, I've only used the apps occasionally. I've logged in a few times to monitor the printing process via the camera and receive notifications when the print jobs are finished. I don't have any major complaints.

Verdict

Ultimately, when evaluating these two 3D printers, the choice largely depends on what you are looking for: simplicity or greater functionality. From experience, the Flashforge Adventurer 5M Pro is characterized by simplicity and reliability - while using it, I had to face one printing problem, which was easily diagnosed and resolved.

Meanwhile, the Anycubic Kobra S1 Combo offers more options, advanced features, and smooth operation. However, although rare, due to the longer plastic supply path, more internal modules, and sensors, technical glitches here may require more time and precision in finding the source of the problem.

However, this 3D printer, while in rare cases it may require more maintenance and cost a little more, offers significantly more features, flexibility and options for that difference. Meanwhile, the Adventurer 5M Pro remains a great choice for those looking for a more basic, easier to maintain and reliable tool for everyday tasks.